The glue-injection bridge-breaking process is a process in which special insulation glue is injected into the cavity of the casement window architectural aluminum profile to form a continuous insulation layer. Compared with the strip-type bridge-breaking process, the glue-injection bridge-breaking process has significant advantages in thermal insulation performance, structural strength and sealing.

The choice of thermal insulation glue is key. High-quality thermal insulation glue not only has excellent thermal insulation properties and can effectively block heat transfer, but also forms a strong bonding layer after curing to firmly bond the aluminum alloy profiles together, thus ensuring the stability of the broken bridge structure. performance and durability. This bonding layer not only improves the overall strength of the broken bridge structure, but also enhances the shear resistance of the profile, allowing the casement window to maintain stable performance during long-term use.

The glue-injection bridge-breaking process has unique advantages in the continuity of the thermal insulation layer. Since the heat-insulating glue can fill every corner of the cavity of the aluminum alloy profile, it can form a continuous heat-insulating layer and effectively block the path of heat transfer. This continuous insulation layer not only improves the thermal insulation effect, but also enhances the thermal insulation performance of the profile, allowing the casement window to maintain a stable indoor temperature in cold or hot climate conditions.

The glue-injection bridge-breaking process also has significant advantages in terms of sealing. Due to the filling and curing of the thermal insulation glue, the sealing performance of the broken bridge structure has been greatly improved. This sealing performance not only helps prevent the intrusion of outdoor noise, dust and rainwater, but also improves indoor air tightness and water tightness, providing residents with a more comfortable and quiet living environment.

The production process of the glue-injection bridge-breaking process is relatively complex, but every step is crucial and directly related to the quality of the final product. The following are the main production processes and technical points of the glue-injection bridge-breaking process:

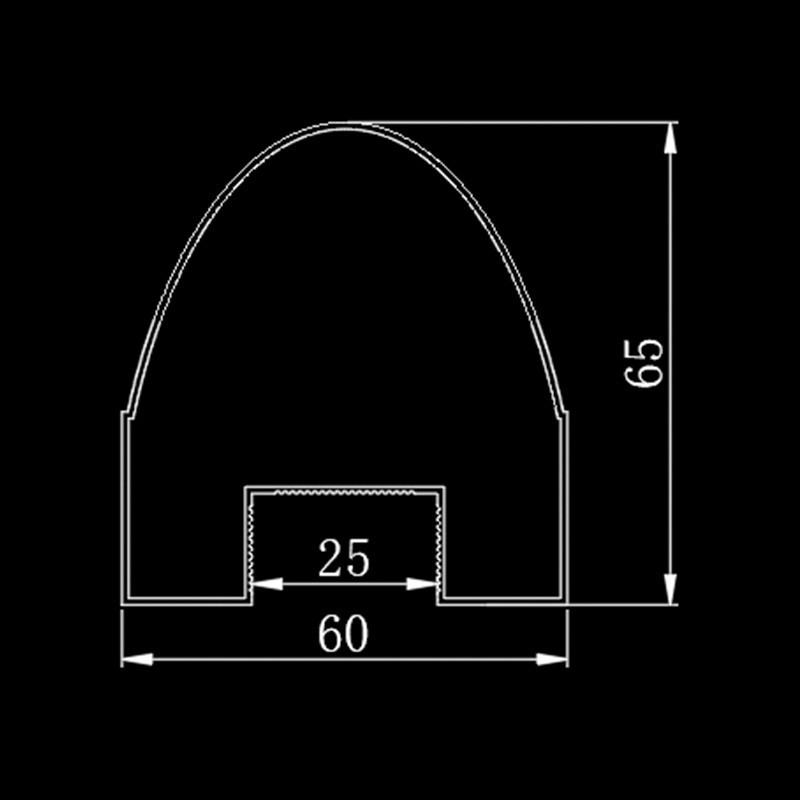

Preparation of aluminum alloy profiles: First, you need to select high-quality aluminum alloy profiles as the base material. These profiles should have good mechanical properties and corrosion resistance to meet the requirements for building exterior windows. At the same time, the size and shape of the profile also need to be processed accurately according to the design requirements.

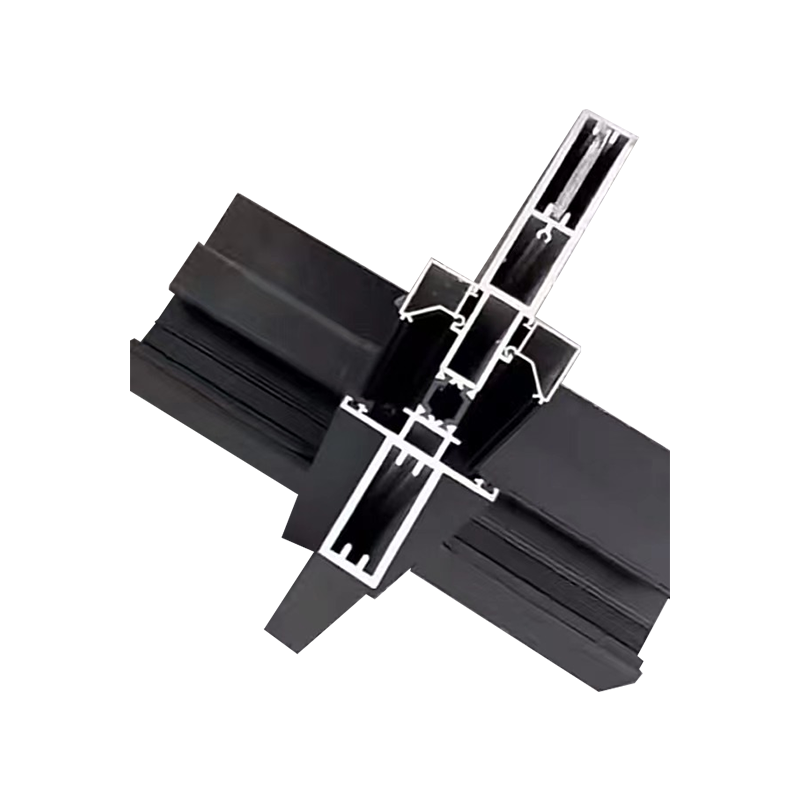

Design of broken bridge structure: Design a broken bridge structure in the cavity of the aluminum alloy profile to determine the injection position and quantity of thermal insulation glue. The design of the broken bridge structure should take into account the stress conditions of the profile and the thermal insulation performance requirements to ensure the stability and thermal insulation effect of the final product.

Selection and injection of heat-insulating glue: Select high-quality heat-insulating glue and inject it into the cavity of the aluminum alloy profile according to the design requirements of the broken bridge structure. During the injection process, the injection speed and pressure of the thermal insulation glue need to be controlled to ensure that the insulation glue can evenly fill the cavity and form a continuous insulation layer.

Curing and inspection: After injecting the insulation glue, it needs to be cured. During the curing process, conditions such as temperature and humidity need to be controlled to ensure that the insulation glue can fully cure and form a strong bonding layer. After curing is completed, the broken bridge structure needs to be inspected, including thermal insulation performance testing, structural strength testing, sealing verification, etc., to ensure that the quality of the final product meets the design requirements.

The application of glue-injection bridge-breaking technology in aluminum profiles for casement window construction not only improves the thermal insulation performance of the product, but also brings many other advantages.

The application of glue-injection bridge-breaking technology significantly improves the thermal insulation performance of casement windows. Due to the excellent thermal insulation performance of thermal insulation glue and the formation of a continuous insulation layer, casement windows can effectively block heat transfer and reduce the temperature difference between indoor and outdoor, thus reducing the energy consumption of air conditioning and heating systems. This energy-saving effect not only helps reduce living and operating costs, but also meets current society's requirements for green, environmentally friendly, and sustainable development.

The application of glue-injection bridge-breaking technology improves the structural strength and durability of casement windows. Since the heat-insulating glue forms a strong bonding layer after curing, the aluminum alloy profiles are firmly bonded together, allowing the casement window to maintain stable performance during long-term use. This improvement in structural strength and durability enables casement windows to maintain stable performance under harsh climate conditions, providing residents with a safer and more reliable living environment.

The application of glue-injection bridge-breaking technology also improves the sealing performance and sound insulation effect of casement windows. Due to the filling and curing of the thermal insulation glue, the sealing performance of the broken bridge structure has been greatly improved. This sealing performance not only helps prevent the intrusion of outdoor noise, dust and rainwater, but also improves indoor air tightness and water tightness, providing residents with a more comfortable and quiet living environment. At the same time, due to the thermal insulation performance of thermal insulation glue, the glue-injection bridge-breaking process can also improve the sound insulation effect of casement windows to a certain extent, providing residents with a quieter indoor environment.

The application of the glue-injection bridge-breaking process also brings design flexibility. Since the filling and curing of thermal insulation glue can form a continuous insulation layer, designers can flexibly design the location and shape of the broken bridge structure according to the shape and style requirements of the building's exterior windows. This design flexibility not only helps meet the creative needs of architects, but also enhances the overall aesthetics and coordination of building exterior windows.

ENG

ENG

English

English русский

русский 中文简体

中文简体 Español

Español bahasa Indonesia

bahasa Indonesia