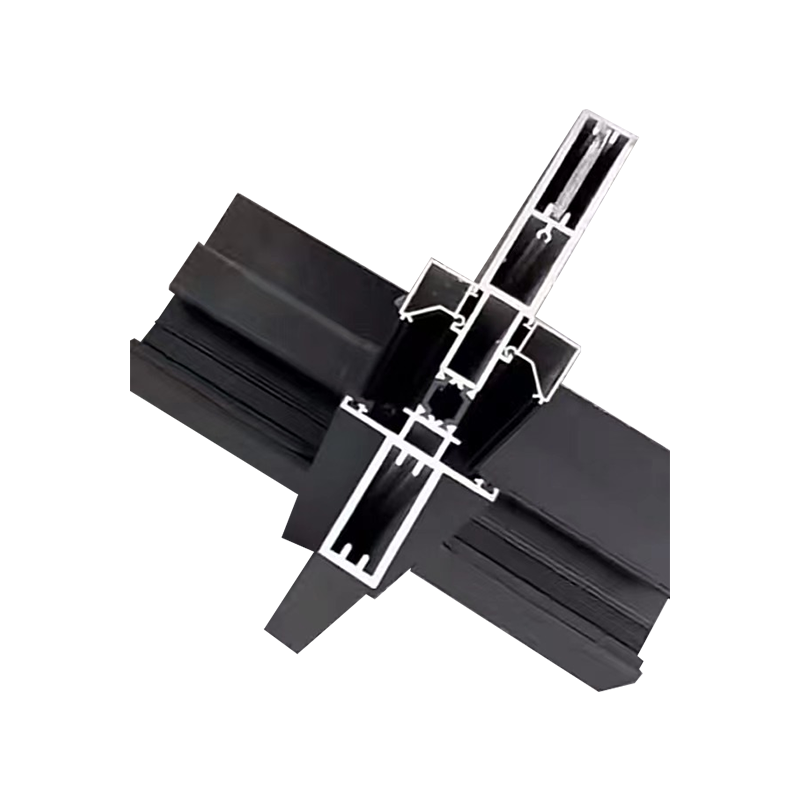

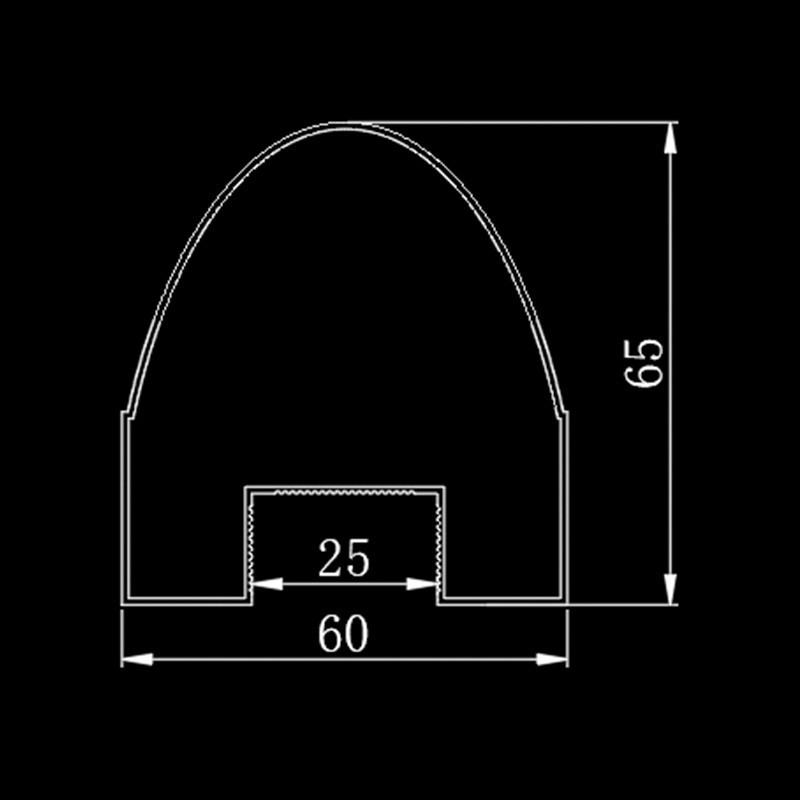

The biggest highlight of the 120 series aluminum alloy curtain wall aluminum profiles is its excellent load-bearing capacity. This capability is not accidental but results from its carefully designed cross-sectional dimensions and structural characteristics. Compared with other series of aluminum profiles, the 120 series significantly improves its structural strength and load-bearing performance by increasing the cross-sectional width and wall thickness while maintaining its lightweight characteristics.

1. Optimized design of cross-sectional dimensions

Cross-sectional size is one of the key factors in the load-bearing capacity of aluminum profiles. The cross-sectional design of the 120 series aluminum profiles fully considers mechanical principles and practical application requirements. By increasing the cross-sectional width and wall thickness, the bending strength and shear strength of the profiles are effectively improved. This design not only enhances the load-bearing capacity of the profile, but also improves its overall stability, making the 120 series aluminum profiles perform well when withstanding loads such as heavy wind pressure and dead weight.

2. Mechanical effects of increased wall thickness

Wall thickness is another important indicator of the load-bearing capacity of aluminum profiles. While maintaining the lightweight characteristics, the 120 series aluminum profiles significantly improve their compression, tensile and torsion resistance by appropriately increasing the wall thickness. This design enables the 120 series aluminum profiles to maintain structural integrity and stability when subjected to complex loads, thereby ensuring the safety and durability of the curtain wall system.

In addition to its excellent load-bearing capacity, 120 series aluminum alloy curtain wall aluminum profiles also have a series of technical advantages, which together form a solid foundation for its industry-leading position.

1. Advanced production technology

The production process of 120 series aluminum alloy curtain wall aluminum profiles follows strict process standards and quality control. From raw material selection to cutting, stamping, welding, grinding and polishing, advanced production equipment and technical means are used. This production process not only ensures the dimensional accuracy and shape stability of the aluminum profile, but also improves its surface quality and corrosion resistance.

2. Diverse design options

120 series aluminum alloy curtain wall aluminum profiles provide diverse design options to meet the needs of different architectural scenarios. Whether it is a glass curtain wall in a modern commercial center or a picture window in a high-end residential area, 120 series aluminum profiles can provide customized solutions. This design flexibility not only improves the building's aesthetics, but also enhances its functionality and practicality.

3. Easy to install and maintain

The installation and maintenance process of 120 series aluminum alloy curtain wall aluminum profiles is relatively simple. Its standardized connection methods and design make the installation process more efficient and faster; while its corrosion resistance and easy cleaning characteristics reduce long-term operating costs and increase the overall value of the building.

The excellent load-bearing capacity and technical advantages of 120 series aluminum alloy curtain wall aluminum profiles have made it widely used in the field of high-rise building curtain walls. The following are some typical application scenarios and case studies:

1. Glass curtain wall of high-rise building

In glass curtain walls of high-rise buildings, 120 series aluminum profiles have become an ideal choice for supporting glass panels due to their excellent load-bearing capacity and stability. Whether it is the exterior decoration of skyscrapers or the transparent domes of large public buildings, 120 series aluminum profiles can provide stable and reliable support to ensure the safety and durability of the curtain wall system.

2. Viewing windows in high-end residential areas

In high-end residential areas, the design of picture windows must not only consider aesthetics and functionality, but also ensure safety and durability. 120 series aluminum profiles have become an ideal material for making viewing windows due to their light weight, high strength and corrosion resistance. Its excellent load-bearing capacity enables the viewing window to withstand large wind pressure and self-weight loads, ensuring the safety and comfort of residents.

3. Transparent domes of large sports venues

In large sports venues, the design of transparent domes not only improves the lighting effect and aesthetics of the venues, but also enhances the audience's viewing experience. 120 series aluminum profiles have become an ideal choice for supporting transparent domes due to their excellent load-bearing capacity and stability. Its lightweight characteristics reduce the dome's dead weight, while its excellent load-bearing capacity ensures the safety and stability of the dome when it withstands high wind pressure and dead weight loads.

ENG

ENG

English

English русский

русский 中文简体

中文简体 Español

Español bahasa Indonesia

bahasa Indonesia