The waterproof and airtight performance of aluminum profiles for sliding window buildings is one of the basic requirements for it as a building component. The key to achieving these performances lies in the sealing treatment between profiles and glass, and between profiles. High-quality sealing materials, as the core of this sealing treatment, play a vital role.

Silicone sealant and EPDM rubber strips are two commonly used sealing materials in sliding window buildings. Silicone sealant, with its excellent weather resistance, aging resistance and chemical stability, has become the first choice for sealing the gaps of doors and windows. It can effectively fill the tiny gaps between profiles and glass, and between profiles, forming a continuous sealing line to prevent rainwater leakage and air convection. Silicone sealant also has good elasticity, which can adapt to the slight deformation of doors and windows during use and maintain the durability of the sealing effect.

EPDM rubber strips, with their excellent weather resistance, aging resistance and elasticity, have become the ideal choice for sliding window sealing strips. It fits tightly into the notch of the profile, forming a solid barrier that effectively blocks the penetration of rainwater and air. EPDM strips also have good wear resistance and tear resistance, which can maintain their sealing performance for a long time and extend the service life of doors and windows.

The quality and performance of sealing materials directly determine the waterproof and airtight performance of sliding windows. High-quality sealing materials, such as high-quality silicone sealants and EPDM strips, have excellent weather resistance, aging resistance and elasticity, and can effectively prevent rainwater leakage and air convection. They can maintain stable performance under extreme climatic conditions, such as high temperature, low temperature, and humidity, to ensure the sealing effect of doors and windows.

On the contrary, inferior sealing materials, due to their poor weather resistance, aging resistance and elasticity, are prone to aging, cracking, and falling off during long-term use, resulting in a decrease in the sealing performance of doors and windows, or even loss of sealing effect. This will not only affect the comfort and energy efficiency of the building, but may also pose a threat to the safety of the building.

Therefore, in the design and manufacturing process of sliding windows, high-quality sealing materials must be strictly selected to ensure that their quality and performance meet relevant standards and specifications. It is also necessary to regularly inspect and maintain the sealing materials, and timely detect and replace aging sealing materials to maintain the waterproof and airtight performance of doors and windows.

In the design and manufacturing process of sliding windows, the selection and application of sealing materials is an important consideration. Different sealing materials have different performance and characteristics and are suitable for different environments and conditions. When selecting sealing materials, it is necessary to comprehensively consider factors such as weather resistance, aging resistance, elasticity, wear resistance, and tear resistance according to the specific requirements and use environment of sliding windows to select the most suitable sealing materials.

In addition, in the application process of sealing materials, the following points should also be noted:

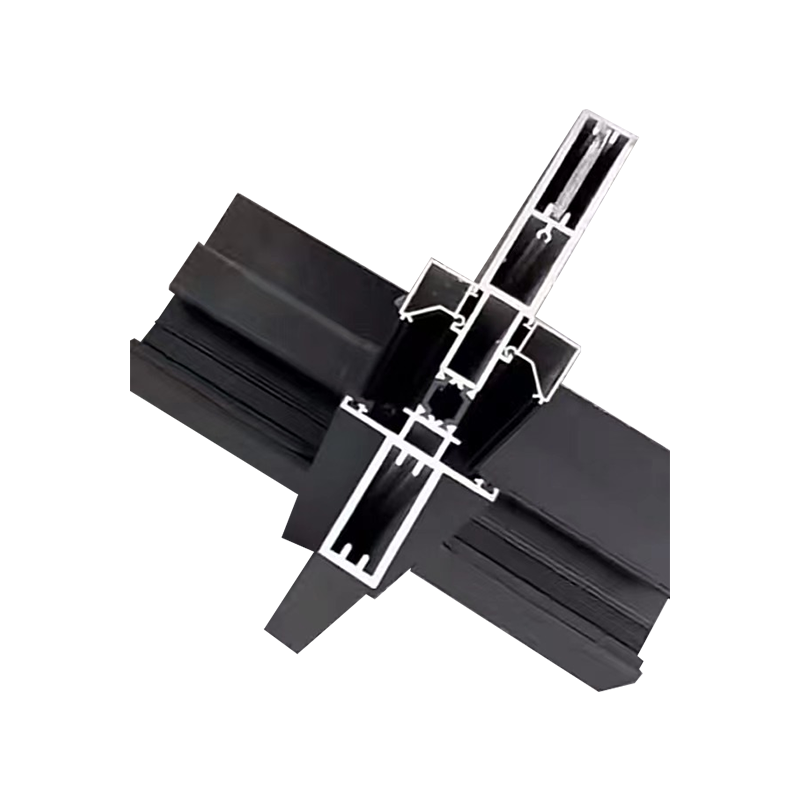

Installation of sealing materials: The installation of sealing materials must be carried out in strict accordance with relevant standards and specifications to ensure close fit and firm connection between them and components such as profiles and glass. During the installation process, special installation tools and sealants are required to ensure the installation quality and sealing effect of sealing materials.

Maintenance of sealing materials: Regularly inspect and maintain the sealing materials of sliding windows to detect and replace aging sealing materials in a timely manner. During maintenance, special cleaning agents and maintenance agents should be used to avoid damage to the sealing materials.

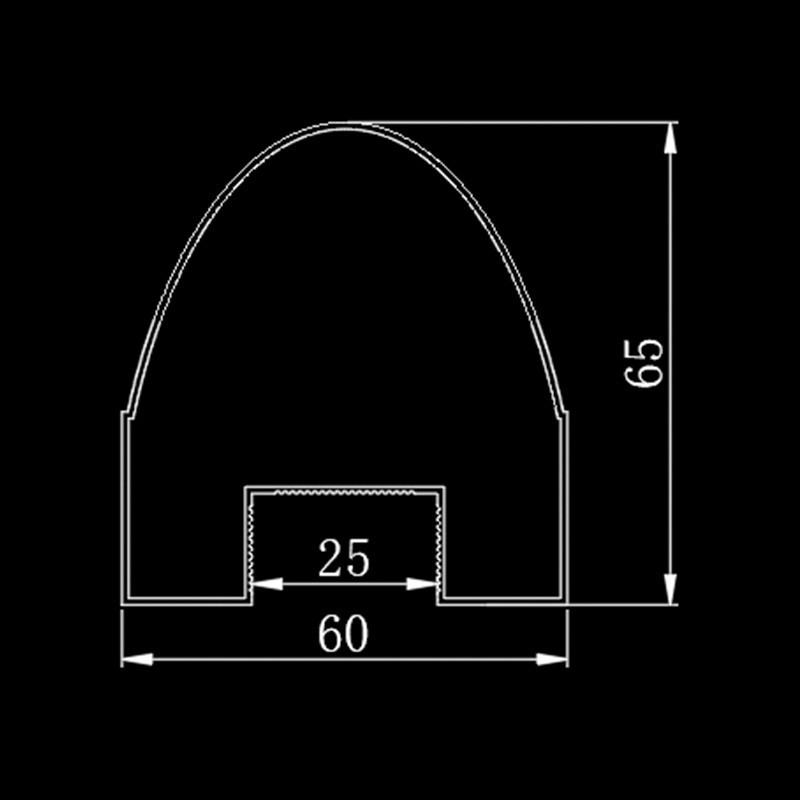

Matching of sealing materials: During the design and manufacturing of sliding windows, attention should be paid to the matching between sealing materials and other components. For example, silicone sealants need to be compatible with the materials of profiles, glass and other components to avoid chemical reactions or corrosion. The EPDM rubber strip needs to match the notch size of the profile to ensure that it can fit tightly in the notch to form an effective sealing barrier.

With the continuous development of modern construction technology and the continuous improvement of people's requirements for building quality, the waterproof and airtight performance of sliding window building aluminum profiles will also face higher requirements and challenges. In the future, the waterproof and airtight performance of sliding window building aluminum profiles will show the following development trends:

Research and development and application of high-performance sealing materials: With the continuous advancement of materials science, more high-performance sealing materials will be developed and applied to sliding window buildings. These new sealing materials will have better weather resistance, aging resistance and elasticity, which can further improve the waterproof and airtight performance of sliding windows.

Application of intelligent sealing system: With the continuous development of the Internet of Things and intelligent technology, the sealing system of sliding window architectural aluminum profiles will be more intelligent in the future. For example, through sensors and control systems, the sealing status of doors and windows can be monitored in real time, and the performance and status of sealing materials can be automatically adjusted according to environmental conditions to maintain the best sealing effect.

Environmental protection and sustainability: With people's increasing attention to environmental protection and sustainability, the sealing materials of sliding window architectural aluminum profiles will pay more attention to environmental protection and sustainability in the future. For example, recyclable or biodegradable materials can be used to reduce the impact on the environment.

ENG

ENG

English

English русский

русский 中文简体

中文简体 Español

Español bahasa Indonesia

bahasa Indonesia