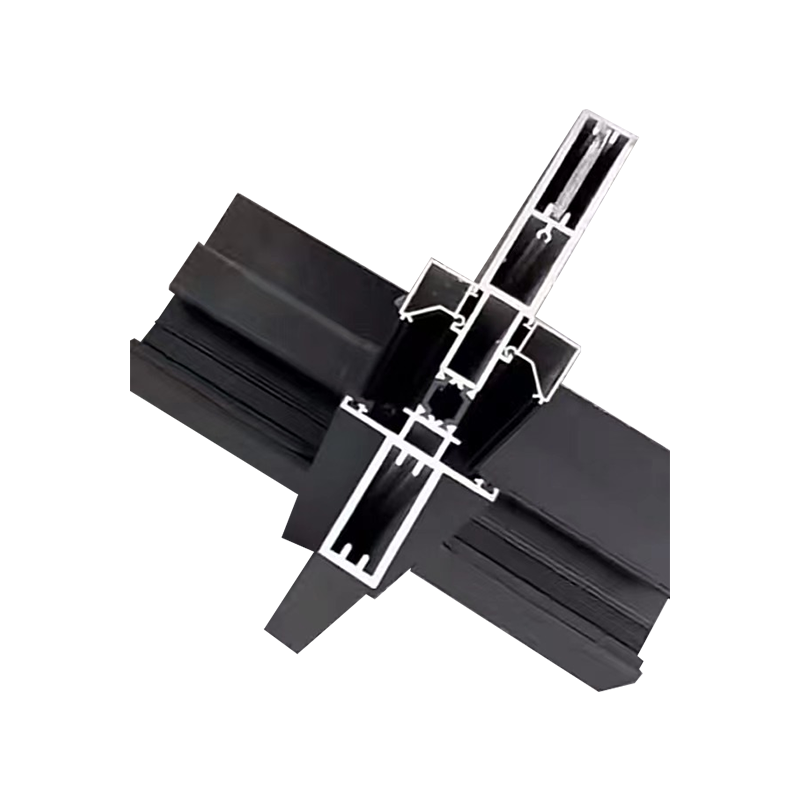

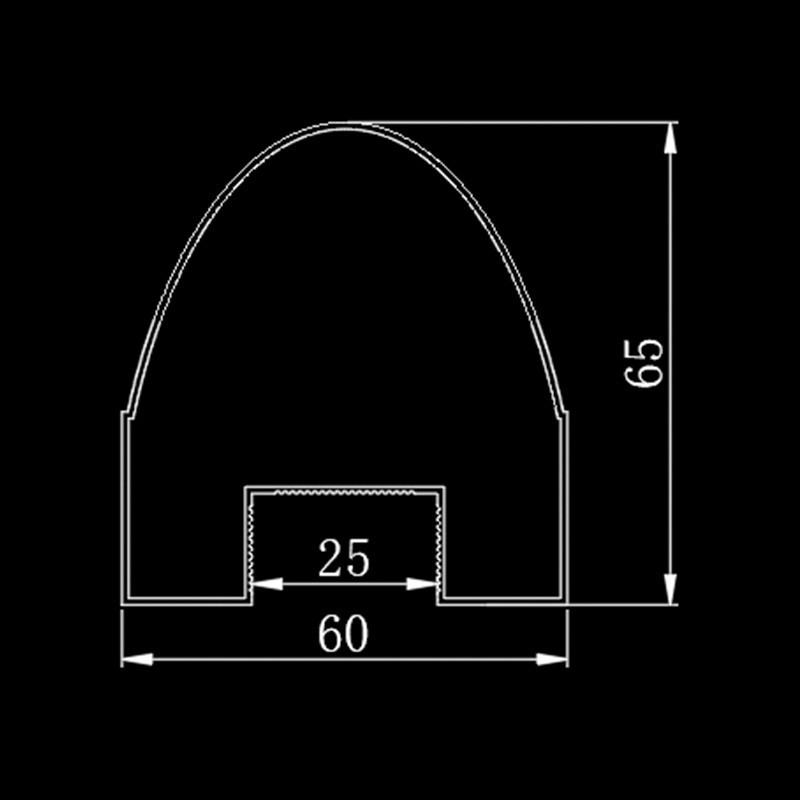

1. Understand project requirements and basic characteristics of aluminum wire profiles

Clarify the specific needs of the project, including but not limited to the required load-bearing capacity, use environment (such as temperature, humidity, corrosive environment), dimensional accuracy, aesthetics, and cost budget. 40*80 Flow aluminum wire profile is widely used in many fields such as construction, transportation, electronics, and mechanical manufacturing due to its light weight, high strength, good corrosion resistance, excellent electrical and thermal conductivity, and easy processing and installation.

2. Analyze the material properties of 40*80 Flow aluminum wire profile

Mechanical properties:

Tensile strength: measures the ability of a material to resist tensile damage, which is particularly important for structures that need to withstand greater tension.

Yield strength: the maximum stress that a material can withstand before plastic deformation, affecting the stability and safety of the structure.

Hardness: reflects the ability of a material to resist local pressure deformation, which is important for wear-resistant and scratch-resistant application scenarios.

Elongation: the maximum amount of plastic deformation that a material can withstand before breaking, affecting the toughness and plasticity of the material.

Corrosion resistance:

Aluminum itself has good corrosion resistance, but additional anti-corrosion treatment may be required in certain environments (such as high humidity, highly corrosive media).

Electrical conductivity and thermal conductivity:

Aluminum is a good conductor and is suitable for applications that require good electrical conduction or heat dissipation, such as electronic equipment and heat exchangers.

Processing performance:

Aluminum is easy to cut, bend, weld and surface treat, and is suitable for the manufacture of complex shapes and structures.

Cost-effectiveness:

Aluminum is relatively light in price and easy to recycle and reuse, which has good economic benefits.

3. Match material properties according to needs

Bearing capacity and structural stability:

According to the bearing capacity required by the project, select aluminum wire profiles with sufficient tensile strength and yield strength.

Considering the overall stability of the structure, it may be necessary to increase the bearing capacity by increasing the cross-sectional size, using reinforcements or changing the cross-sectional shape.

Corrosion resistance:

For aluminum wire profiles used in corrosive environments, alloys with higher corrosion resistance, such as 6061-T6 aluminum alloy, or surface treatments such as anodizing and electrophoretic coating should be selected.

Electrical conductivity and thermal conductivity: For applications that require good electrical conduction or heat dissipation, choose aluminum with high conductivity and consider its thermal conductivity. Pay special attention to the cross-sectional design of aluminum wire profiles to optimize current distribution and heat conduction paths. Processing performance and aesthetics: According to the processing requirements of the project, choose aluminum that is easy to cut, bend and weld. Consider surface treatments such as anodizing, powder coating, etc. to improve aesthetics and corrosion resistance. Cost-effectiveness: On the premise of meeting project requirements, choose aluminum wire profiles with high cost performance. Consider the maintenance cost and replacement cost of long-term use, as well as the recyclability of aluminum. 4. Supplier selection and quality control Choose a reputable supplier: ensure the quality and delivery time of aluminum wire profiles. Check product certifications: such as ISO certification, RoHS certification, etc., to ensure that the product meets relevant standards and regulations. Conduct sample testing: Before bulk procurement, perform performance tests on samples to verify whether they meet project requirements. Establish a quality feedback mechanism: During use, collect quality feedback in a timely manner so that procurement strategies can be adjusted in a timely manner.

ENG

ENG

English

English русский

русский 中文简体

中文简体 Español

Español bahasa Indonesia

bahasa Indonesia